Elementum 3D granted patents in U.S., Canada, and Australia for core technology in metal additive manufacturing

Posted on | June 4, 2020 | No Comments

Contact:

Patrick Callard

720-545-9016 ext. 37

patrick@elementum3d.com

Elementum 3D granted patents in U.S., Canada, and Australia

for core technology in metal additive manufacturing

Reactive Additive Manufacturing (RAM) enables 3D printing of

high-performance metal powders not previously possible

Erie, Colorado – Elementum 3D, a developer and supplier of groundbreaking metal additive manufacturing (AM) materials, announced the issuance of patents in the U.S., Canada, and Australia for its Reactive Additive Manufacturing (RAM) technology. The RAM process significantly expands the potential AM materials library by enabling printing previously unprintable materials.

Through this process, Elementum 3D has introduced a family of new laser powder bed fusion (LPBF) printing materials with superior properties compared to previously available AM materials and corresponding wrought alloys. This success in fusing AM with innovative new materials and desirable-but-previously unprintable traditional manufacturing materials will propel the introduction of new and inventive AM applications.

Elementum 3D specializes in materials and process development. Its team leverages deep, specialized expertise to create advanced metal alloys, superalloys, and metal ceramic composites. Elementum 3D uses RAM technology to create printable, high-performance alloy powders based on established wrought alloys, including aluminum 1000, 2024, 6061, 7050, and 7075.

Popular high strength wrought aluminum alloys could not previously be printed because they suffer hot tearing (solidification cracking), resulting in parts with very poor mechanical properties. The RAM process forms sub-micron inoculants in the melt pool that nucleate aluminum grains to produce a fine equiaxed microstructure for good printability and exceptional performance. By making AM versions of these alloys widely available, Elementum 3D eliminates material compromises and democratizes materials freedom.

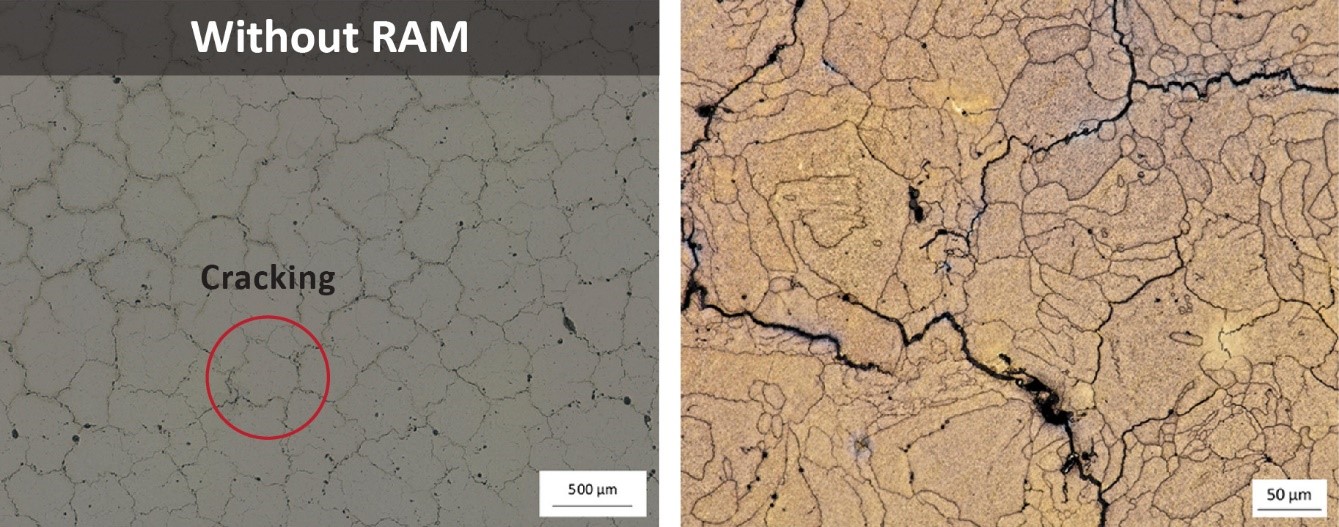

An unmodified “standard” 6061 aluminum alloy is shown in Figure 1 after printing and polishing. The Figure 1 left-hand micrograph shows a low magnification image of the polished and unetched growth plane with the large grain structure and the network of intergranular cracking clearly visible. Figure 1’s right-hand image shows a higher magnification micrograph of the same material etched with Weck’s reagent showing the cracking network.

Figure 1. Unmodified “standard” 6061 aluminum alloy after printing by laser powder bed fusion showing large grains and an extensive network of intergranular cracking. The left-hand image is unetched and the right-hand micrograph is etched with Weck’s reagent and taken at higher magnification.

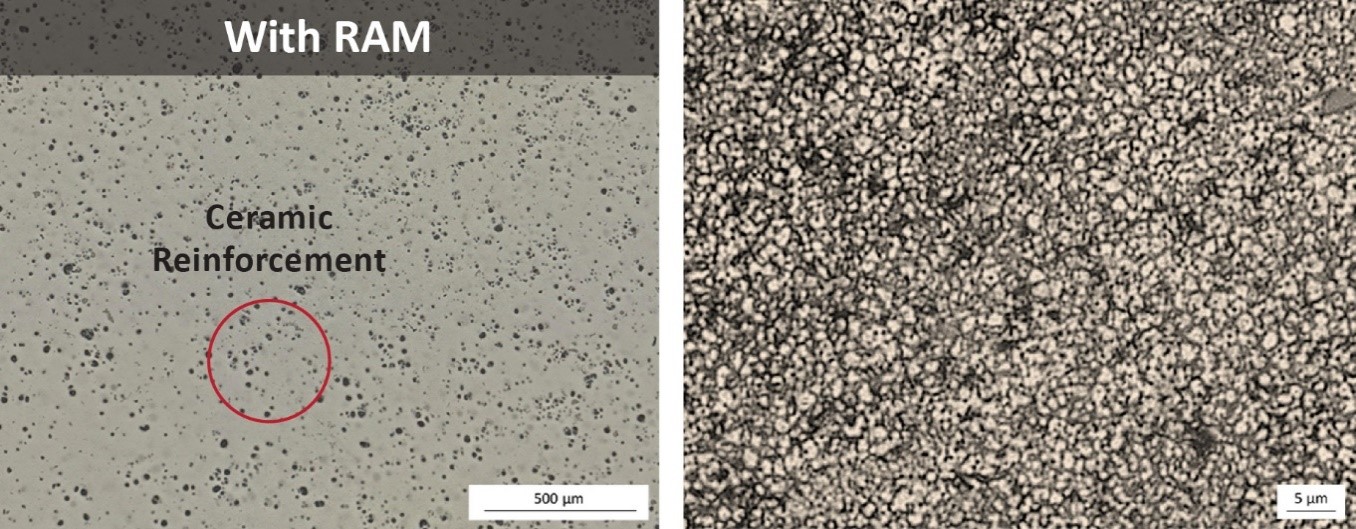

The Elementum 3D A6061-RAM2 printed material is shown in Figure 2 with the left-hand image showing a crack-free microstructure with a dispersion of nucleating and reinforcing particulates. The right-hand Figure 2 image shows a higher magnification view of the same material etched by Weck’s reagent revealing the fine equiaxed aluminum grain structure that gives the A6061-RAM2 material its exceptional printability and properties.

Figure 2. Elementum 3D’s A6061-RAM2 aluminum alloy showing a crack-free microstructure with the darker phase comprising reinforcing particles and the very fine (1-2 µm) aluminum grains revealed after etching with Weck’s reagent in the higher magnification image on the right.

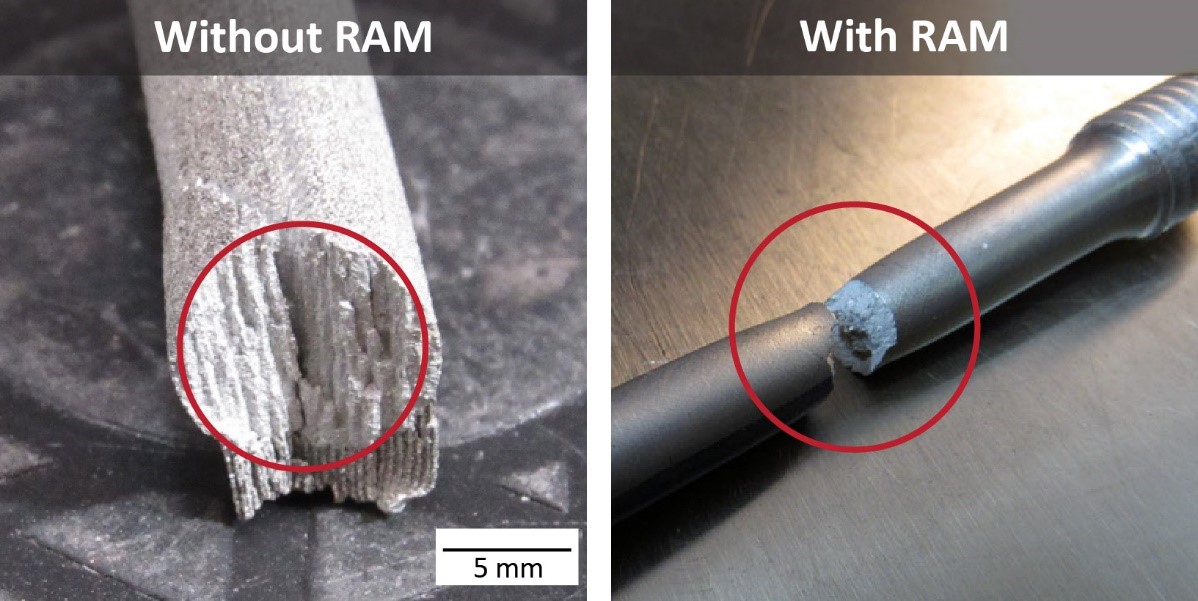

Figure 3. Unmodified “standard” 2024 aluminum alloy without RAM addition exhibits columnar grain growth.

Figure 4. Elementum 3D’s A6061-RAM2 aluminum alloy with RAM addition exhibits ductal behavior.

Elementum 3D excels in developing custom materials tailored for a myriad of applications and sells unique feedstock powders with precise printing process parameters. Its feedstock powders can be further customized for specific applications, giving Elementum 3D customers the materials freedom they demand to increase product strength, durability, and performance and reduce weight and cost.

The AM industry is the new frontier of metal manufacturing. It brings many advantages to developing game changing applications in aerospace, automotive, defense, and other industries. However, limited selection of printable metal materials constrains wider adoption. “Our revolutionary technology advances metals development for additive manufacturing at an unprecedented pace. It gives engineers the extra degree of freedom they have never experienced, inspiring them to bring into existence new and innovative applications,” said Dr. Jacob Nuechterlein, President and Founder.

About Elementum 3D

Elementum 3D was founded by Dr. Jacob Nuechterlein in 2014. Elementum 3D’s mission is to significantly expand the selection of metals additive manufacturing materials by introducing advanced metal alloys, superalloys, and composites, optimized printing processes, performance data, and expert guidance that saves time and money and reduces AM frustration. Find more on Elementum 3D at elementum3d.com, and on LinkedIn, Facebook, and Twitter.

###

For more Elementum 3D news, visit https://www.elementum3d.com/news.

To access this news release on Google Docs, visit this link:

https://docs.google.com/document/d/1q-t0E3HKWCKd-AtXeMARc_e4vd-4Tg2Ss7rjJrdOz-s/edit?usp=sharing

Comments

Leave a Reply