Elementum 3D Earns First-Ever Gold Medal Awarded by U.S. Air Force Advanced Manufacturing Olympics

Posted on | November 12, 2020 | No Comments

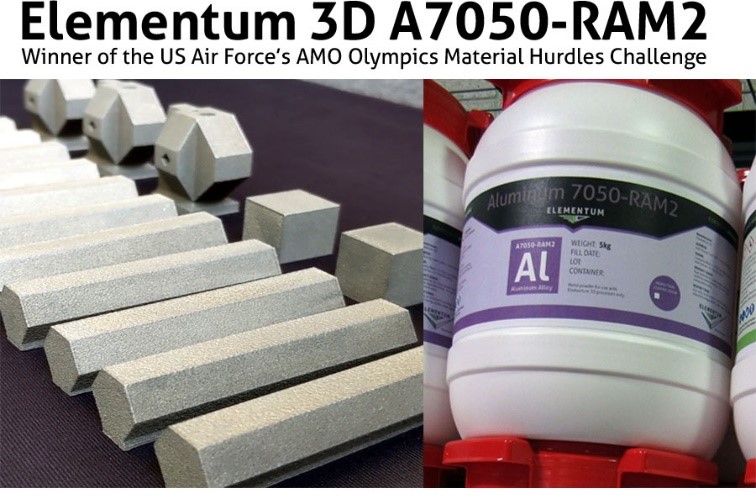

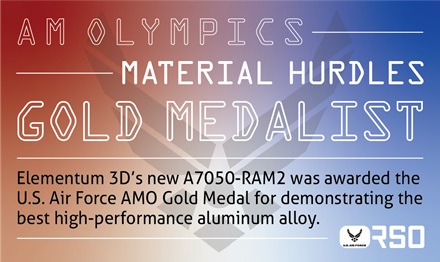

Erie, Colorado – Elementum 3D, a developer and supplier of groundbreaking metal additive manufacturing (AM) materials, earned first place at the inaugural U.S. Air Force Advanced Manufacturing Olympics (AMO). The company won the event’s “Material Hurdles” technical challenge with its A7050-RAM2 high-strength aluminum alloy, beating eight other finalists.

Sixty-four teams participated in the AMO competition, hosted by the USAF Rapid Sustainment Office (RSO). Each team completed five technical challenges judged by 25 experts from academia, the U.S. military, and aerospace and defense companies, the FAA, Ford, and Amazon. Each team was required to accurately recreate 3D printed parts from an existing Technical Data Package using innovative materials and techniques while demonstrating accuracy, skill, completeness, ease of use, and speed of production.

The RSO “Material Hurdles” challenge saw teams compete to accurately recreate 3D printed parts in their own specialized material. Dr. Jacob Nuechterlein, president and founder of Elementum 3D, explained, “We entered our A7050-RAM2 aluminum alloy to deliver on the AMO event’s initiative to obtain a material capable of being 3D printed into components for use in demanding Air Force conditions.”

The USAF is implementing additively manufactured aluminum alloys because they can be produced quickly and on-demand while reducing component weights and raw material requirements. Employing advanced manufacturing can also reduce the sustainment costs of the RSO, which currently make up 70 percent of the USAF budget. Elementum 3D’s printable A7050-RAM2 feedstock supports these goals by allowing the USAF to 3D print components out of an aluminum material that is lightweight, high-strength, and offers both excellent fatigue life and stress corrosion cracking resistance.

“We are honored to have our commercially available high-strength A7050-RAM2 aluminum alloy selected as the AM material to best meet the USAF’s challenge goal of demonstrating advances in AM aluminum material properties to address sustainment of traditionally manufactured 7075 and 7050 aluminum parts,” said Nuechterlein.

The U.S. Air Force has a long history of fostering innovative solutions and these AM Olympics technical challenges were the latest means in generating transformative opportunities within advanced manufacturing. It sets in motion the USAF’s willingness to embrace leading-edge solutions making for a more sustainable Air Force.

About Elementum 3D

Elementum 3D was founded by Dr. Jacob Nuechterlein in 2014. Elementum 3D’s mission is to significantly expand the selection of metals additive manufacturing materials by introducing advanced metal alloys, superalloys, and composites, optimized printing processes, performance data, and expert guidance that saves time and money and reduces AM frustration. Find more on Elementum 3D at elementum3d.com, and on LinkedIn, Facebook, YouTube, and Twitter. For more Elementum 3D news, visit https://www.elementum3d.com/news.

###

News: Manhard Consulting Opens Austin Office

Posted on | November 11, 2020 | No Comments

Manhard Consulting Opens Austin Office

New location serves growing region

AUSTIN, TX and LINCOLNSHIRE, IL – National civil engineering and surveying firm Manhard Consulting has opened a new office in Austin, Texas. The firm’s newest location, its 10th office nationwide, is managed by Jesse Conrad, VP, who is based in the company’s Dallas office and responsible for managing all of Texas. Austin has been a target market for Manhard, and after careful analysis, the opportunity to bring the right associates onto the team, and given the region’s growth, it made sense to establish a presence here.

In addition to Conrad as manager, new Manhard team members based in Austin include Adam Burke, PE, project manager and associate principal; Casey Giles, PE, senior project manager and associate principal; and John Lewis, who will manage projects and work on business development.

“These leaders support the growth in the Austin area, and the office complements our existing presence in Texas,” said Don Manhard, Jr., President and CEO. “This move aligns with our steady approach to growth, and to better serve our clients across the region. Austin is a perfect fit — a diverse and expanding market, a great opportunity to grow, and it aligns well with our national strategy.”

Recent Texas projects the firm has had a role in include:

- Sierra Vista in Iowa Colony, TX — engineering and surveying services for development of 900-acre, 1,800-lot master-planned community

- Sapphire Bay in Rowlett, TX — civil engineering, land planning, surveying, entitlement, and construction administration services for a 117-acre, $1 billion mixed-use development

- Valley View-DFW Commerce Park in Dallas, TX — civil engineering for onsite and offsite improvements for a three-building industrial park totaling approximately 1.6 million square feet on 120 acres.

“Given the explosive growth in that market, and the top-tier talent we’ve recruited to build our foundation locally, we’re excited at the potential for us here, and beyond, for our newest office and future Texas opportunities,” noted Conrad.

Manhard Consulting’s new Austin team members are located at 2101 E. St. Elmo, Building 1, Suite 100, Austin. The firm has had a Texas presence for 5 years, and the new location will work closely with Manhard’s existing office in Dallas, and its other offices across the country.

About Manhard Consulting

Manhard Consulting is a full-service civil engineering and surveying firm that serves public and private clients nationwide. With more than 275 employees, and 10 offices across the United States, Manhard Consulting continues to lead the industry as one of the most responsive, innovative and technologically advanced civil engineering and surveying firms in the country. Learn more about Manhard on LinkedIn, Twitter, Facebook, and Instagram.

###

Adam Burke, PE, project manager and associate principal

Casey Giles, PE, senior project manager and associate principal

John Lewis, project manager

Elementum 3D granted patents in U.S., Canada, and Australia for core technology in metal additive manufacturing

Posted on | June 4, 2020 | No Comments

Contact:

Patrick Callard

720-545-9016 ext. 37

patrick@elementum3d.com

Elementum 3D granted patents in U.S., Canada, and Australia

for core technology in metal additive manufacturing

Reactive Additive Manufacturing (RAM) enables 3D printing of

high-performance metal powders not previously possible

Erie, Colorado – Elementum 3D, a developer and supplier of groundbreaking metal additive manufacturing (AM) materials, announced the issuance of patents in the U.S., Canada, and Australia for its Reactive Additive Manufacturing (RAM) technology. The RAM process significantly expands the potential AM materials library by enabling printing previously unprintable materials.

Through this process, Elementum 3D has introduced a family of new laser powder bed fusion (LPBF) printing materials with superior properties compared to previously available AM materials and corresponding wrought alloys. This success in fusing AM with innovative new materials and desirable-but-previously unprintable traditional manufacturing materials will propel the introduction of new and inventive AM applications.

Elementum 3D specializes in materials and process development. Its team leverages deep, specialized expertise to create advanced metal alloys, superalloys, and metal ceramic composites. Elementum 3D uses RAM technology to create printable, high-performance alloy powders based on established wrought alloys, including aluminum 1000, 2024, 6061, 7050, and 7075.

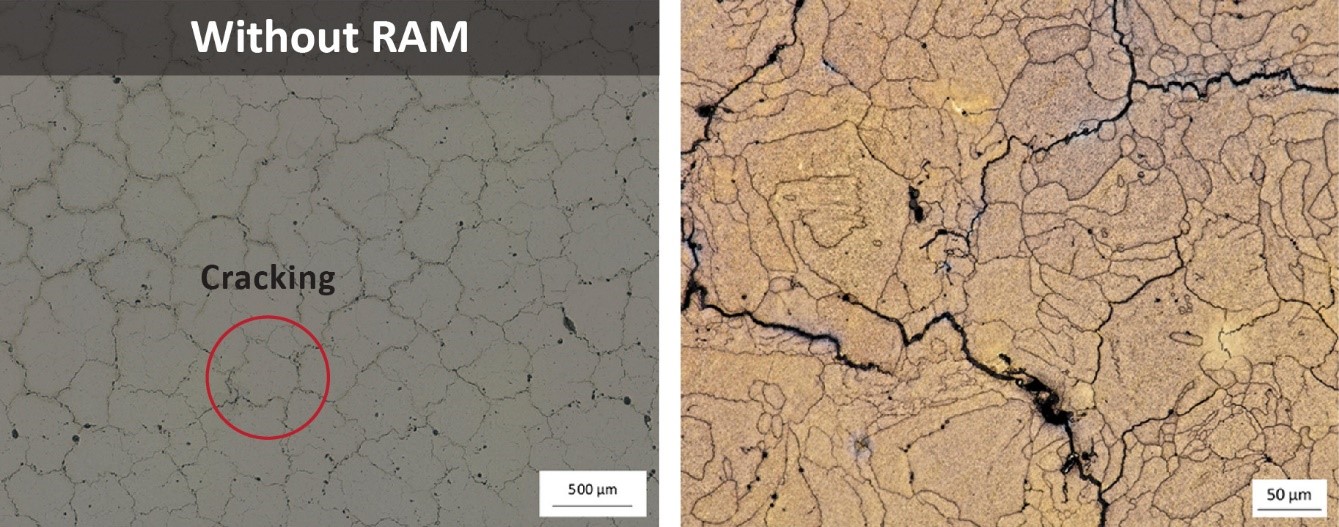

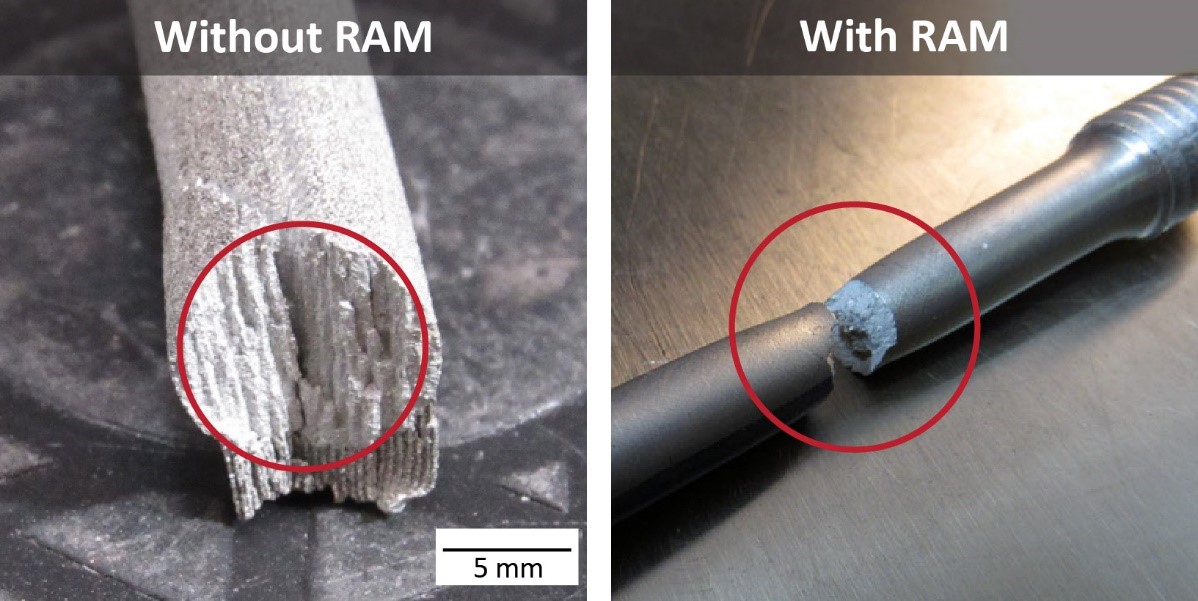

Popular high strength wrought aluminum alloys could not previously be printed because they suffer hot tearing (solidification cracking), resulting in parts with very poor mechanical properties. The RAM process forms sub-micron inoculants in the melt pool that nucleate aluminum grains to produce a fine equiaxed microstructure for good printability and exceptional performance. By making AM versions of these alloys widely available, Elementum 3D eliminates material compromises and democratizes materials freedom.

An unmodified “standard” 6061 aluminum alloy is shown in Figure 1 after printing and polishing. The Figure 1 left-hand micrograph shows a low magnification image of the polished and unetched growth plane with the large grain structure and the network of intergranular cracking clearly visible. Figure 1’s right-hand image shows a higher magnification micrograph of the same material etched with Weck’s reagent showing the cracking network.

Figure 1. Unmodified “standard” 6061 aluminum alloy after printing by laser powder bed fusion showing large grains and an extensive network of intergranular cracking. The left-hand image is unetched and the right-hand micrograph is etched with Weck’s reagent and taken at higher magnification.

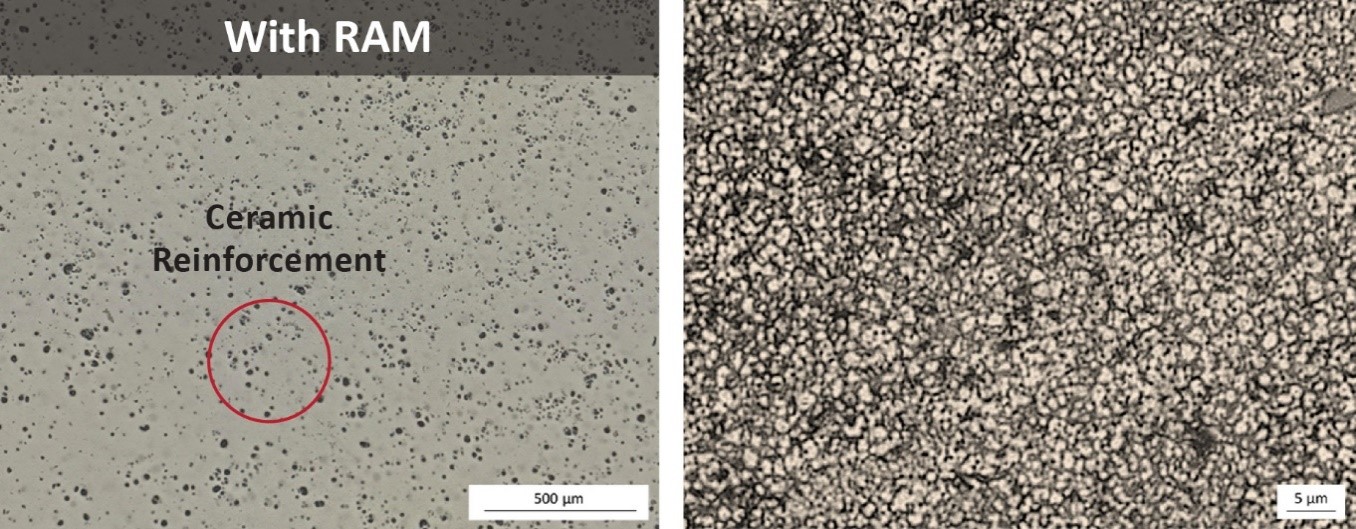

The Elementum 3D A6061-RAM2 printed material is shown in Figure 2 with the left-hand image showing a crack-free microstructure with a dispersion of nucleating and reinforcing particulates. The right-hand Figure 2 image shows a higher magnification view of the same material etched by Weck’s reagent revealing the fine equiaxed aluminum grain structure that gives the A6061-RAM2 material its exceptional printability and properties.

Figure 2. Elementum 3D’s A6061-RAM2 aluminum alloy showing a crack-free microstructure with the darker phase comprising reinforcing particles and the very fine (1-2 µm) aluminum grains revealed after etching with Weck’s reagent in the higher magnification image on the right.

Figure 3. Unmodified “standard” 2024 aluminum alloy without RAM addition exhibits columnar grain growth.

Figure 4. Elementum 3D’s A6061-RAM2 aluminum alloy with RAM addition exhibits ductal behavior.

Elementum 3D excels in developing custom materials tailored for a myriad of applications and sells unique feedstock powders with precise printing process parameters. Its feedstock powders can be further customized for specific applications, giving Elementum 3D customers the materials freedom they demand to increase product strength, durability, and performance and reduce weight and cost.

The AM industry is the new frontier of metal manufacturing. It brings many advantages to developing game changing applications in aerospace, automotive, defense, and other industries. However, limited selection of printable metal materials constrains wider adoption. “Our revolutionary technology advances metals development for additive manufacturing at an unprecedented pace. It gives engineers the extra degree of freedom they have never experienced, inspiring them to bring into existence new and innovative applications,” said Dr. Jacob Nuechterlein, President and Founder.

About Elementum 3D

Elementum 3D was founded by Dr. Jacob Nuechterlein in 2014. Elementum 3D’s mission is to significantly expand the selection of metals additive manufacturing materials by introducing advanced metal alloys, superalloys, and composites, optimized printing processes, performance data, and expert guidance that saves time and money and reduces AM frustration. Find more on Elementum 3D at elementum3d.com, and on LinkedIn, Facebook, and Twitter.

###

For more Elementum 3D news, visit https://www.elementum3d.com/news.

To access this news release on Google Docs, visit this link:

https://docs.google.com/document/d/1q-t0E3HKWCKd-AtXeMARc_e4vd-4Tg2Ss7rjJrdOz-s/edit?usp=sharing

Manhard Consulting Opens Northern Colorado Office

Posted on | May 22, 2020 | No Comments

Manhard Consulting Opens Northern Colorado Office

New Loveland location better serves growing Northern Colorado region

LOVELAND, CO and LINCOLNSHIRE, IL – National civil engineering and surveying firm Manhard Consulting has opened a new office in Loveland, Colorado. The firm’s newest location, its 11th office nationwide, is managed by Weston Spears, PLS. Spears has 25 years of experience with surveying and engineering projects for residential, oil and gas, energy, retail, and other sectors, including roles in redeveloping Lowry Air Force Base and Stapleton International Airport.

“Given Northern Colorado’s rapid growth and our expanding client base along the Front Range, we’ve been looking for an opportunity to establish a local presence,” said Don Manhard, Jr., President and CEO. “We are thrilled to welcome Weston and his team and look forward to growing here and being closer to our projects in the region.”

Recent Northern Colorado projects the firm has had a role in include:

- Mead Place, Mead. Engineering and surveying for approximately 160 acres and 300+ single-family lots, a 30-acre pad for commercial development, and a 13-acre pad for multi-family development. Challenges included the relocation of an existing irrigation ditch through the property and approximately 6,000 linear feet of state highway and county road improvements.

- Springs at Sandstone Phase 2, Longmont. Engineering and surveying as part of the design and approval process for Longmont multi-family development on 20 acres. Includes 10 residential buildings, clubhouse, and amenities including a three-acre open space park. Challenges included steep slopes on the western portion of the site.

- Multi-family development, Greeley. Engineering and surveying to support the design and approval of 17 acres with 12 residential buildings, clubhouse, and amenities.

- Retail facility, Fort Collins. Engineering and surveying for 5,000-square-foot retail space including parking, detention, and underground utilities.

“We’re excited to welcome Weston and his team,” said Jim Roake, PLS, Manhard’s national director of land surveying. “With decades of combined experience providing services supporting residential, industrial, retail, and energy sectors, they are a great addition while giving us a local presence in Northern Colorado and the clients and projects we have in the area.”

Manhard Consulting’s new office is at 2893 N. Monroe Avenue in Loveland. The firm has had a Colorado presence for 20 years, and the new location will work closely with Manhard’s existing office in Greenwood Village, CO, and its nine other offices across the country.

About Manhard Consulting

Manhard Consulting is a full-service civil engineering and surveying firm that serves public and private clients nationwide. With more than 275 employees, 11 offices across the United States, and more than 10,000 clients, Manhard Consulting continues to lead the industry as one of the most responsive, innovative and technologically advanced civil engineering and surveying firms in the country. Learn more about Manhard on LinkedIn, Twitter, Facebook, and Instagram.

###

Access a Google doc of this release and a photo of Weston Spears:

https://docs.google.com/document/d/1OwAC2dFWle68k_lTBjAdyshQBMcUd7H0-bSpjfgrwWs/edit?usp=sharing

News: Elementum 3D Achieves ISO 9001 Certification

Posted on | May 14, 2020 | No Comments

Contact:

Patrick Callard

720-545-9016 ext. 37

patrick@elementum3d.com

Kerri Williams, President

k.wi@platinumregistration.com

303-639-9001

Elementum 3D Achieves ISO 9001 Certification

Erie, Colorado – Elementum 3D, a developer and supplier of groundbreaking metal additive manufacturing (AM) materials, today announced that it has achieved ISO 9001:2015 certification for quality management.

The scope of Elementum 3D certification, issued through Denver-based ISO 9001 management certification firm Platinum Registration, Inc., includes the design and manufacture of advanced metals, superalloys, and composites; development of new manufacturing processes; and the manufacture of prototype and production parts to customer specifications.

“This is an important milestone for Elementum 3D,” said Dr. Jacob Nuechterlein, Elementum 3D President and Founder, “It’s a rigorous process to become ISO 9001 certified. Our staff worked very hard with Platinum Registration’s auditors to demonstrate we meet the requirements of the standard. Not only does that make us feel confident we’re the most efficient that we can be, it assures our customers that we have a completely transparent and robust management system; and that means we have reliable, repeatable, continuously improving business processes so that our customers receive the best value for their money.”

Dr. Nuechterlein further said that implementing management procedures in accordance with the high standards of ISO 9001:2015 allows Elementum 3D to solidify its world-class position in the industry and provide its customers with the confidence they’ve partnered with the industry leader.

About ISO 9001:2015

Established by the International Organization for Standardization, ISO 9001:2015 is recognized as the worldwide standard for quality management systems and practices. The standards body provides requirements, guidance, and tools for companies and organizations that want to ensure their products and services consistently meet customer requirements and that quality is consistently improved. It can be used by any organization, large or small, regardless of its field of activity.

ISO 9001:2015 has been implemented by over one million companies and organizations in over 170 countries. More detail at: http://www.iso.org/iso/home/standards/management-standards/iso_9000.htm

About Platinum Registration

Platinum Registration is a Denver-based, ANAB-accredited management system certification body. Over one million organizations worldwide are independently certified, making formal management system standards the most widely used management tools in the world today. Platinum’s clients include service and manufacturing organizations in North America and Canada. Platinum’s audits ensure that clients conform to international and national standards, assuring customer satisfaction and positioning them for growth in the marketplace. For more information, visit platinumregistration.com.

About Elementum 3D

Elementum 3D was founded by Dr. Jacob Nuechterlein in 2014. Elementum 3D’s mission is to significantly expand the selection of metals additive manufacturing materials by introducing advanced metal alloys, superalloys, and composites, optimized printing processes, performance data, and expert guidance that saves time and money and reduces AM frustration. Find more on Elementum 3D at elementum3d.com, and on LinkedIn, Facebook, and Twitter.

###

For more Elementum 3D news, visit https://www.elementum3d.com/news.

To access this news release on Google Docs, visit this link:

https://docs.google.com/document/d/1h6INeLpja6PosUyh2sKOOv_fQzEmAtqNli9I9yENgoU/edit?usp=sharing

Faustson VP Hostetter Named to 2020 Governors Fellowship Class

Posted on | June 15, 2019 | No Comments

23 Colorado business and community leaders embark on year-long CiviCO program around policy, life, and public service

Arvada, CO – Faustson, a worldwide leader in machining and additive manufacturing, is pleased to announce that its VP Heidi Hostetter has been named to the 2020 class of Colorado Governors Fellows. This group of 23 business and community leaders will spend the next year studying issues and preparing to help shape policy and perception of life and public service in Colorado. The group was inducted into the program on June 27, 2019 by Governor Jared Polis.

“I am so excited to participate in this program alongside some of Colorado’s strongest private sector leaders. Learning from them and implementing policy together feels like impactful and necessary work,” said Hostetter. “I have always believed, even before creating the ADAPT center through the state’s infrastructure program, that public/private partnerships are necessary to the success of what we do – especially as Colorado is growing so rapidly and we face infrastructure concerns due to that fast-paced growth.”

The leadership program is in its fourth year, modeled after the White House Fellows Program and Dr. Geoff Smart’s book “Leadocracy,” in partnership with the University of Colorado School of Public Affairs and the Governor’s Office with funding from the Boettcher Foundation. All of Colorado’s living governors are supporters of the program, as well.

“Colorado has a unique opportunity to elevate the brand of Colorado government by supporting emerging leaders who have a desire to serve the public sector,” Polis said in a statement. “The success of our state will be enhanced by the pipeline of talented emerging leaders from the Governors Fellowship Program. We are proud of their commitment and look forward to the incredible work they will achieve for Colorado’s future.”

The other 22 members of the 2020 Governors Fellowship Class include:

- Adam Burrows, founder of Lava Walk Ventures in Denver.

- Jennifer Chang, regional manager for Cisco Systems in Denver.

- Jeremy Duhon, founder and curator of TEDxMileHigh in Denver.

- Nic Eliason, group vice president for DaVita in Denver.

- Nicole Garneau, curator and Health Sciences Department chair of the Denver Museum of Nature & Science.

- Shawn Gullixson, vice president of Vectra Bank Colorado in Colorado Springs.

- Sonia Gutierrez, real estate broker for The Christi Reece Group in Grand Junction.

- Meghan Herwehe, senior vice president of strategy and analytics for CorePower Yoga in Denver.

- Elizabeth Katkin, co-owner and general counsel of LDK Logistics Inc. in Englewood.

- Adeeb Khan, director of corporate social responsibility at TIAA in Denver.

- Patrick Loney, director of patient care services at the Pediatric Mental Health Institute at Children’s Hospital Colorado in Aurora.

- Michael Mansheim, executive director of marketing at Colorado Mesa University in Grand Junction.

- KJ McCorry, CEO of Officiency Inc. in Boulder.

- Blessing “Yemi” Mobolade, small business development administrator for the city of Colorado Springs.

- Chris Otto, partner at Plante Moran in Fort Collins.

- Mia Ramirez, community partner for the Colorado Trust in Colorado Springs.

- Jake Schroeder, executive director for the Denver Police Activities League Inc.

- Adam Silver, senior credit analyst for ArrowMark Partners in Denver.

- Jonathan Steenland, chief operating officer for the National Cybersecurity Center in Colorado Springs.

- Anna Stout, executive director of the Roice-Hurst Humane Society in Grand Junction.

- Cori Streetman, co-founder and principal of Barefoot PR in Denver.

- Emily Wattman-Turner, chief operating officer for the Kenzie Academy in Denver.

“We have phenomenal community leaders around our state,” CiviCO’s executive director Eric Hopfenbeck said in a statement. “It’s thrilling to see the interest in public service and passion for elevating Colorado. We are deeply honored to steward this program to elevate the brand of government and inspire public service.”

About Faustson

Faustson, a worldwide leader in the machining industry, provides services for clients worldwide in the medical, aerospace, aeronautics, defense, semiconductor and other industries. Faustson has been at the forefront of the manufacturing industry since 1982, continuing a tradition of pioneering the newest technology and pushing its limits. The company, woman-owned and -operated small business, takes on challenging applications using state-of-the-art precision machining to do things no one else in the industry thinks can be done. The company provides additive manufacturing/3D metal printing, 3-, 4- and 5-axis milling and 5-axis EDM services, as well as turning capabilities for cutting-edge custom part production and efficient production of standard parts. Learn more by visiting their website, Facebook, Twitter, or LinkedIn.

About CiviCO

In 1999, Quarterly Forum (QF) was founded to provide a place for emerging executives to do more, learn more and become more. What began as a breakfast with Mike Fries, Scott Reiman and then entrepreneur, John Hickenlooper, has emerged as the state’s premier community leadership development organization. QF was built with a spirit of collaboration and a commitment to civic responsibility. QF is now CiviCO. We are nearly 300 graduates and members strong with educational programs spanning the public, private and social sectors across the state. With a universal mindset to ensure Colorado will always thrive and grow, we aim to be the enduring pulse of the community.

When you join the CiviCO community, you are committed to a way of life and a culture that will elevate your significance in the community and catalyze a good life, a better Colorado, and the best you.

CiviCO is grateful for its partners who believe in its work to inspire community leaders across Colorado. The organization is deeply appreciative of those who take pride in their role as stewards of Colorado and who graciously commit their time to participate in CiviCO programs and membership platforms. Their commitment empowers our mission. CiviCO’s Community Partner is the Boettcher Foundation; its Thought Partner is McKinsey & Company; its Academic Partner is University of Denver; and its Mentor Partner is River.

###

Manhard Consulting Opens New Katy, Texas Office

Posted on | June 4, 2019 | No Comments

Fourth Texas office is closer to key clients and projects, strengthens presence in and commitment to the Houston area

HOUSTON, TX – National civil engineering and surveying firm Manhard Consulting has opened a new office in Katy, Texas. The location will be home to Manhard’s commercial site team, led by Senior Project Manager Guillo Machado, PE, who manages industrial, office, multi-family, and mixed-used projects for the greater Houston area and beyond. The Katy office will also handle residential and land development, one of Manhard’s core services nationally, for projects in the region.

“We’re thrilled to have the workload and reach in the Houston area and Texas to support this location. With a growing list of clients, partners, projects, and team members in Katy and the surrounding region, this new location will make it more convenient for everyone to connect,” said Jon Unterreiner, Region Manager – Houston Operations. “It also gives us better access to the talented workforce in the Katy area as we continue to grow locally and statewide.”

The Katy location is the firm’s fourth office since it established a presence in Texas, joining existing offices in The Woodlands, Dallas-Fort Worth and San Antonio.

Manhard associates in the area or visiting from one of the firm’s 10 other offices nationwide will be able to work from the Katy or Woodlands offices, depending on their needs and the locations of the clients and projects they’re working on.

About Manhard Consulting

Manhard Consulting is a full-service civil engineering and surveying firm that serves public and private clients nationwide. Our associates collaborate with your teams to address safety, functionality, and quality-of-life issues where it matters most: on your site, in the community, in everyday life. With more than 250 employees, 11 offices across the United States and over 10,000 clients, Manhard Consulting continues to lead the industry as one of the most responsive, innovative and technologically advanced civil engineering and surveying firms in the country. Learn more about Manhard on LinkedIn, Twitter, Facebook, and Instagram.

###

NoCO Manufacturing Partnership Announces NOCOM 2019 Speaker Schedule

Posted on | April 8, 2019 | No Comments

Loveland, Colorado— Northern Colorado Manufacturing Partnership (NoCO) has announced the full slate of speakers for NOCOM 2019, its fifth annual conference at The Ranch on April 11, 2019. Sessions will address topics ranging from strategic partnerships to the talent pipeline. The NOCOM 2019 Speaker Hall is sponsored by AuerCPA Co. and FirstBank. All speakers will present in the South Hall.

“After in-depth research with Partnership members, we planned, solicited and selected this speaker slate carefully,” said Christina Haxton, Chief Potential Officer at The Center for Sustainable Strategies, who managed the process. “We worked to balance presentations about technology, the supply chain, and ongoing concerns manufacturers have around personnel, including hiring and workforce development. We have some great speakers presenting important, useful information that members and NOCOM attendees will find valuable.”

10:00-10:45 a.m. Manufacturing Workforce Solutions: Plan for today and the future!

Trevor Pruitt, Associate, Skillful – Colorado

Andrew Palmer, Advanced Manufacturing Program Manager at CareerWise Colorado

Practical, affordable strategies you need to fill your talent pipeline.

11:00-11:45 a.m. How to STOP the COP-OUT Syndrome & Build a Culture of Ownership in Your Organization: A 4-Part Framework for Manufacturers & Supply Chain Companies

Christina Haxton, Chief Potential Officer at The Center for Sustainable Strategies

Insights, strategies and best practices from interviews with executives and CEOs of successful Colorado companies who are building a Culture of Ownership.

1:30-2:00 p.m. Best Practices for Strategic Partnering to Increase Performance & Profit

Bob Forshay, APICS Northern Colorado

Dan Van Arsdall, Global Supply Chain Manager, Rubadue Wire

How to partner strategically and intentionally to deliver on time, on budget, and on promise.

2:00-2:45 p.m. Taking the Manufacturing Journey to Operational Excellence: Reports from the Field

Josh Owens, Sales Engineer at TMMI powered by GrayMatter

Mark Morse, Enterprise Sales Specialist at GrayMatter Systems

Advancing your operation through digital processes and predictive analytics to outperform – close the loop between manufacturing and business systems to get the most out of your operations.

Note: for full details on each session and bios and photos of each speaker, visit this link for a Google doc:

https://docs.google.com/document/d/1P2-426V-gBhn0LLayLuyMfKjJ1llQU4PJ18yI5u0vDo/edit?usp=sharing

“NOCOM is a unique opportunity to expand your business where it matters,” said Bob Forshay, Supply Chain Pro 2 Know. “Local leaders investing in their and your growth through collaboration and learning. We all profit when we gain competitive advantage. My 30+ years in manufacturing and supply chain management has shown me the value of strategically leveraging your supply chain partners, add capabilities, flexible capacity and reducing the risk overall”.

“We hope folks come to us with questions, are open minded, and ready to learn,” said Dan Van Arsdall, Global Supply Chain Manager, Rubadue Wire. “Whether that’s from us, other speakers, exhibitors, fellow attendees. There are so many folks doing it differently from the status quo, and your best approach is to learn, network, collaborate and think strategically. You’ll find lots of ideas you can borrow and paraphrase and modify, and we’re all here to learn from one another.”

The NOCOM Student Experience

NOCOM 2019 is proud to host high school students for a NOCOM Student Experience where students will enjoy lunch with a speaker. From 1:00 to 2:00 p.m. they will walk the trade show floor and have an opportunity to talk with exhibitors about what their organizations offer the future workforce, including tuition reimbursement, internships, job shadows, and more.

“The NOCOM show is such great exposure for students,” said Josh Weissman, technology education teacher at Poudre High School in Fort Collins. “We can show them real opportunities in the community today. What engineers do in the real world. What assemblers do. What machinists make. They get lunch, and get a look at what 130 different companies are doing, in one stop, under one roof.”

About the 5th Annual NOCOM Trade Show

NOCOM 2019 takes place Thursday, April 11th, 2019, The Ranch Events Complex, in Loveland, Colorado. For more information or to register, visit www.nocomfg.com.

Date: Thursday, April 11th, 2019

Time: 9:00 a.m. to 3:30 p.m.

B2B Networking Reception 4:00 to 6:00 p.m. (separate ticket required)

Featuring Colorado OEDIT Executive Director Betsy Markey

For more information and to register for this event, visit www.nocomfg.com. For more information on sponsorships and to become a corporate sponsor, contact Adam Papilion, NOCOM 2019 Chair, at 970-692-3344 or adam@h2manufacturingsolutions.com.

About Northern Colorado Manufacturing Partnership

The NoCo Manufacturing Partnership was formed in 2013 as a result of Governor Hickenlooper’s state Economic Development plan called the Colorado Blue Print. The Blue Print identified 11 key sectors of the economy in Colorado by region. Northern Colorado’s two main sectors identified were Health and Wellness and Advanced Manufacturing. Regions within the state were encouraged to form sector partnerships to provide more localized grass roots support to augment state efforts in each sector. These would be industry specific, led by business, in partnership with economic development, education and workforce development. A collaboration arose as part of the Blue Print process involving people from each of these affiliations and the NoCo Manufacturing Partnership was born. It continues to be an all-volunteer, business led, FREE membership organization designed to support Northern Colorado manufacturers. It is served by a Board of Directors, representing each affiliation from private business to local government, as well as two active committees: Networking and Manufacturing Talent/Rocks! Find us on the web, Facebook, Twitter and LinkedIn.

###

To view this release online, visit this Google doc link:

https://docs.google.com/document/d/1OAyv2PqWs2AuJka0l3HgBwlbgNhkaIfpKy5dMLx0Vmg/edit?usp=sharing

ADAPT Consortium Welcomes New Member Lithoz – Lithoz assists with ceramic printer install at Colorado School of Mines

Posted on | March 2, 2019 | No Comments

Golden, CO – The Alliance for the Development of Additive Processing Technologies (ADAPTSM), an industry-academia consortium that advances data informatics and advanced characterization technologies to Optimize for AdditiveSM, welcomes new member Lithoz, the world leader in development and production of ceramic materials and additive manufacturing (AM) systems.

Lithoz connected with ADAPT through a research collaboration with Professors Corinne Packard and Geoff Brennecka at Colorado School of Mines. Mines is currently investigating mechanical properties of ceramics produced by lithography-based ceramic manufacturing (LCM) with graduate student Sarah Sortedahl with the intent of exploring whether separate standards are needed for ceramic AM.

“The mechanical properties of ceramics are highly sensitive to material or manufacturing flaws,” said Professor Packard. “Working with Lithoz directly, and having a CeraFab 7500 printer here at Mines, allows us to rapidly evaluate and optimize processes for achieving strength and reliability in AM ceramics.”

“Ceramic additive manufacturing is particularly suited to aerospace and biomedical applications. The representation of these markets in ADAPT’s membership makes Mines and ADAPT a natural partnership. This partnership allowed us to install one of our ceramic printers in a Mines lab. There, it is being used for research and courses focused on AM technology and design for AM,” said Shawn Allan, VP of Lithoz America. “We are excited to see the student research projects that result from this new capability. We also hope to leverage resources such as ADAPT’s Citrination database to improve the utilization and learning that can be achieved with the vast amount of data generated in the LCM process.”

“The Lithoz membership in ADAPT formally marks our commitment to expand ADAPT’s research mission to all solid materials, beyond the alloys focus we had in our first few years,” said ADAPT Executive Director Aaron Stebner.

About Lithoz

Lithoz is the world leader in development and production of ceramic materials and additive manufacturing systems. Ceramics produced with these systems meet the highest demands of industry especially in terms of density, strength and precision. Lithoz was founded in Vienna, Austria, in 2011 based upon research from Vienna University of Technology. Lithoz America was founded in 2017 to support the North American ceramic industry. Learn more at http://www.lithoz.com/en.

About ADAPT

The Alliance for the Development of Additive Processing Technologies (ADAPT) is an industry-academia consortium dedicated to solving challenges in additive manufacturing (AM) using data-driven approaches. Headquartered at Colorado School of Mines, ADAPT was launched in December 2015 with funding from the Colorado Office of Economic Development and International Trade (OEDIT). Founding members include Ball Aerospace & Technologies Corp., Citrine Informatics, Colorado School of Mines, Faustson Tool, Lockheed Martin and Manufacturer’s Edge. For more information, visit the ADAPT website, or find ADAPT on LinkedIn, Twitter, Facebook and Instagram.

###

To view a formatted version of this release with images of the Lithoz CeraFab 7500 installed at Colorado School of Mines, visit:

https://docs.google.com/

Nominations Open for 2019 Colorado Manufacturing Awards – Manufacturers, peers, industry colleagues and others invited to submit nominations by Friday, February 15, 2019

Posted on | January 24, 2019 | No Comments

Denver, CO –The Colorado Manufacturing Awards (CMA), presented by CompanyWeek and Manufacturer’s Edge, has opened nominations for its 4th annual program, culminating in an awards reception and presentation on April 4, 2019 in Denver, Colorado at the Cable Center on the University of Denver campus. Nominations close Friday, February 15, 2019.

The CMAs recognize outstanding manufacturing companies across 12 industries and the supply chain. The program is co-presented by CompanyWeek, digital media and events focusing on manufacturing, and Manufacturer’s Edge (the NIST Manufacturing Extension Partner in Colorado). Three finalists from each industry category will be celebrated throughout March and winners announced at the April 4 event.

Visit ColoradoManufacturingAwards.com for information about the program, including nomination criteria and links to articles and photographs from past awards presentations.

CompanyWeek founder and co-presenter Bart Taylor has first-hand knowledge of many of the manufacturers across Colorado through the publication’s editorial work. “For us, it’s a culmination of a year of reporting on manufacturing companies and the great people of the sector,” said Taylor. “The awards are as much about celebrating the collective accomplishments of the community as they are of exemplary individual performance. That said, it’s impossible not to be blown away by some of the work being done. I’ve said this before: it’s a sector alive with possibilities.”

“The manufacturing sector here is highly underrated,” he added. “It’s also a model for how U.S. manufacturing will develop in the future – innovation and growth across a number of industries. Many have deep roots right here – like the natural food ecosystem and aerospace community – industries that promise considerable growth.”

The CMAs have tapped into Colorado’s robust network of industry trade and support groups to reach out to companies and participate in programming. “The trade associations do such great work, so it’s been great to work with them to recognize the great companies that comprise their memberships,” explained Manufacturer’s Edge CEO Tom Bugnitz. “The companies have something in common – they all have great employees and make great products – and we’ve tapped into the shared experiences and challenges that all manufacturers have, regardless of industry.”

At its heart this is about bringing the community together and celebrating Colorado manufacturing” Bugnitz said. “The program is a win for everyone, especially the nominees and winners, and really highlights the Colorado way of collaboration, sharing, and innovation.”

Companies can be nominated in one of 12 industry award categories:

Aerospace/Electronics Manufacturer of the Year

Bioscience/Medical Manufacturer of the Year

Outstanding Outdoor Industry Brand

Outstand Craft Brewer

Outstanding Craft Distiller

Outstanding Food Brand/Co-Packer

Industrial & Equipment Manufacturer of the Year

Contract Manufacturer of the Year

Builder/Construction Co. of the Year

Outstanding Cannabis Manufacturer

Outstanding Consumer/Lifestyle Brand

Energy Manufacturer of the Year

Companies are encouraged to visit ColoradoManufacturingAwards.com for more information and to submit nominations.

Member companies are also encouraged to contact their association or trade contacts in the following CMA partner organization categories:

Colorado Craft Brewing Guild

Colorado Distilling Guild

Colorado Proud

Colorado Bioscience Association

Colorado Cleantech Industry Association

Rocky Mountain Tooling & Machining Association

Colorado Space Business Roundtable

Co Active

2019 Colorado Manufacturing Awards sponsors include:

UMB, BKD, Hoptocopter Films, Squire Patton Boggs, AssuredPartners, Colorado Office of Economic Development & International Trade, H2 Manufacturing Solutions, Aqua-Hot, and Allay Cannabis Consulting.

About CompanyWeek

CompanyWeek chronicles the manufacturing economy through independent business and leadership profiles. Since 2014, over 900 in-depth company features have been published at www.companyweek.com. Subscribe to weekly CompanyWeek e-publications or view CompanyWeek on the web, Facebook, and Twitter.

###